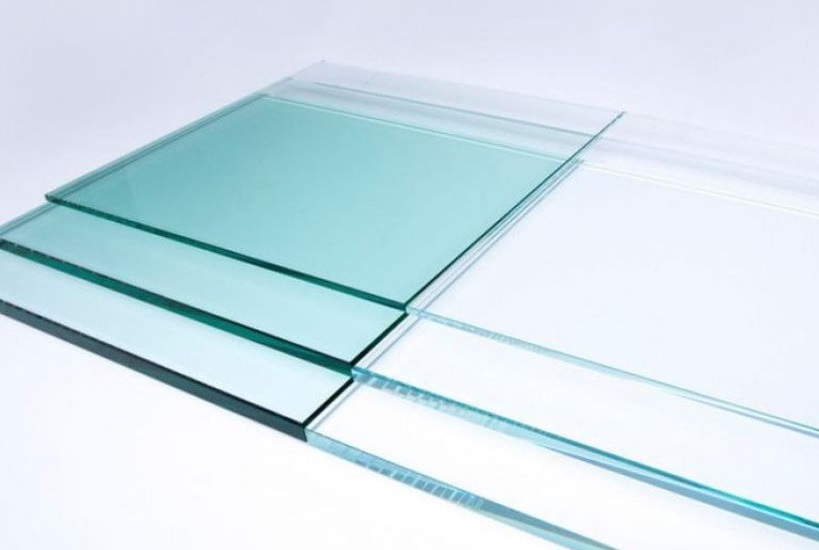

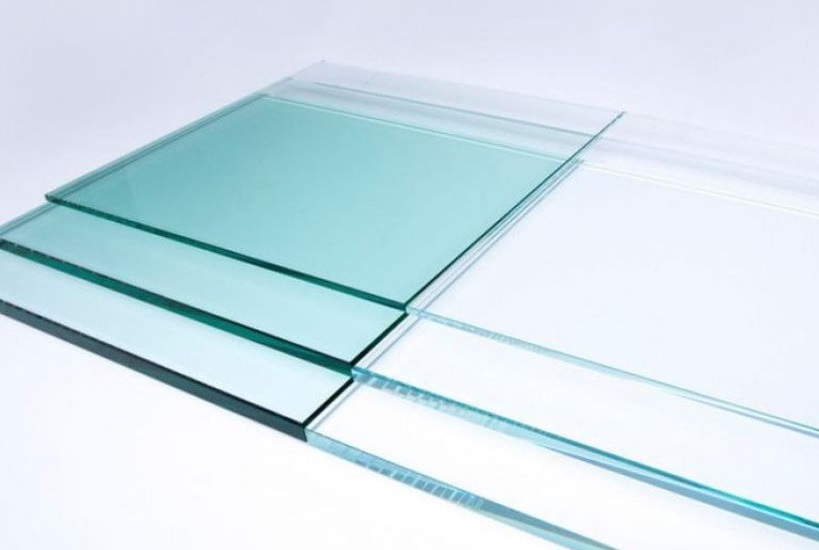

Float Glass

Float glass is extremely smooth, clear, perfectly flat on both sides and seamlessly uniform throughout. It’s also used to make a variety of other types of glass, including toughened and laminated glass.

Why is it called float glass?

Float glass is glass which is made using the “float process”, which involves “floating” a liquid glass mixture over a bed of molten tin to create a molten ribbon of glass. It gently cools as it “floats” over the tin and onto an air or ceramic roller conveyor system, forming a long ribbon of (now solid) glass that is cut and packed for transportation.

History of Float Glass

The float glass process was invented by Sir Alastair Pilkington in the late 1950’s. It is a method of making commercial quality flat glass. The process remains essentially unchanged since its invention, though there have been some minor improvements to the original design over time.

Uses of Float Glass

Float glass is the most commonly used form of glass in the world. Apart from the obvious use in windows and glass facades, float glass is also used for mirrors, car windscreens and camera lenses.

Advantages of Float Glass

- Easily mass produced so doesn’t have the same high price tag as other more artisanal glasses.

- Easily cut to produce perfectly fitting windows, doors and other building components

- This also makes it much cheaper to install than other types of glass

- Excellent transparency which makes it ideal for display cases

Disadvantages of Float Glass

- Dirt and fingerprints are very obvious due to it’s smoothness

- Very brittle and shatters into dangerous shards when broken which presents a safety hazard in areas with high traffic

Elias Chahine

Elias Chahine is the director of Gusto Emergency Glass Replacement and has many years in the glass repair and construction industry