What Causes Spontaneous Glass Breakage?

Can glass shatter on it’s own? Yes! There are a few circumstances by which this may happen as we will discuss in this article.

Is Spontaneous Glass Breakage Common?

Spontaneous glass breakage is an extremely rare occurrence but it does happen from time to time.

While a glass window shattering for no reason may initially seem to be a defect in the manufacturer or production, there are many reasons as to why it might happen after all. The first thing that comes to mind is natural disasters such as earthquakes and wind storms.

The different reasons for spontaneous glass breakage include –

Installation Defects

There are many different factors that could cause a glass window to spontaneously shatter after installation. Some of these include the use of subpar quality replacement windows and fittings or contact with incompatible sealants or nails during installation.

Thermal Stress

When a window is exposed to drastic temperature changes, thermal stress is created around the glass. This can cause spontaneous breakage if not properly tempered or designed for. For example, south facing glass windows exposed to sunlight for most of the day during summer months will experience larger temperature fluctuations than other windows in the home. This makes them more likely to shatter due to thermal stress.

Damaged Edges

Toughened glass comes pre-cut from the factory for installation, so it’s possible that damage to the edges occur when the glass is being packaged, shipped, or installed onsite. Once the edge of a glass panel is damaged, it becomes very weak and likely to spontaneously break if exposed to the right amount of force (eg. high winds)

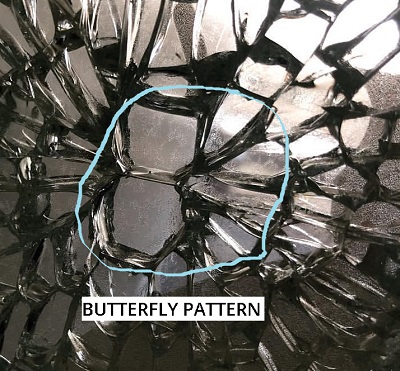

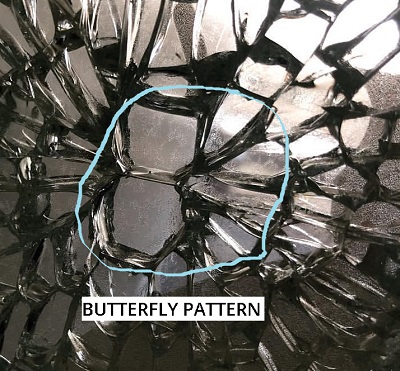

Nickel Sulfide Inclusion

Nickel sulfide inclusions are small particles of nickel and sulfur that form during the manufacturing process for toughened glass. Over time, the nickel sulphide can expand and form micro cracks, causing the glass to shatter without warning. Glass breakage due to nickel sulphide inclusion will display a ‘Butterfly Effect’. This pattern will centre around a singular point on the glass and will fan out in a butterfly wing formation.

How to Prevent Spontaneous Glass Breakage

There are several things you can do to reduce the likelihood of spontaneous glass combustion occurring:

- Use quality replacement windows and fittings

- Ensure compatibility between sealants and windows during installation

- Reduce the chances of thermal stress by installing shading over south facing glass windows during summer months

- Inspect the edges of toughened glass for damage before installation and avoid using subpar equipment during installation

Heat Soaking Glass to Prevent Spontaneous Glass Breakage

Heat soaking is an optional stage in the glass making process that is often used as a quality control method. It entails a controlled heating cycle that exposes toughened glass to elevated temperatures of 290ºC for 2hrs to cause nickel sulphide expansion that would normal occur naturally over time. The process exposes any weak panes that were previously at risk of spontaneous glass breakage due to nickel sulphide inclusions.

This procedure has been shown to identify close to 95% of problematic panes.

Where is Heat Soaked Glass Used?

Heat soaked glass is used in a range of architectural applications including buildings,balustrades, balconies, conservatories and skylights.

Robert Schell has worked in the glass and glazing industry for over 40 years. He is a licensed glazier, and currently works at Gusto Emergency Glass Replacement providing window glass repairs and replacement in the Sutherland Shire area.